![[Translate to Englisch:] Shoutbox](/fileadmin/_processed_/5/3/csm_hdr-platin-sens_30117514fa.jpg)

Since 2014, all new vehicles (according to ECE-R 64) must be equipped with a tyre pressure monitoring system (TPMS). Among other things, these systems are designed to help prevent accidents caused by incorrect tyre pressure or a creeping flat tyre. Optimum air pressure, however, can above all save fuel and help prevent unnecessary tyre wear. The car manufacturers use systems that measure directly on the wheel or indirectly via the rolling circumference of the tyre via ABS.

Direct systems (with TPMS sensor)

With a direct system, the tyre's air pressure is detected by the TPMS sensor installed in the wheel. This information is transmitted wirelessly to a control unit in the vehicle. An on-board computer display is used to show the driver what is happening. A direct system is more complex when changing tyres. The sensors are installed using special tools with a pre-set torque, and special diagnostic devices and software are required for reading out the sensor data, teaching the sensors, etc.

Indirect systems (without TPMS sensor)

With an indirect system, the air loss is detected by the ABS or traction sensors installed on the vehicle. In this case, the use of TPMS sensors is not necessary and nothing extra has to be considered when selling and fitting complete wheels. An indirect system requires recalibration after changing tyres.

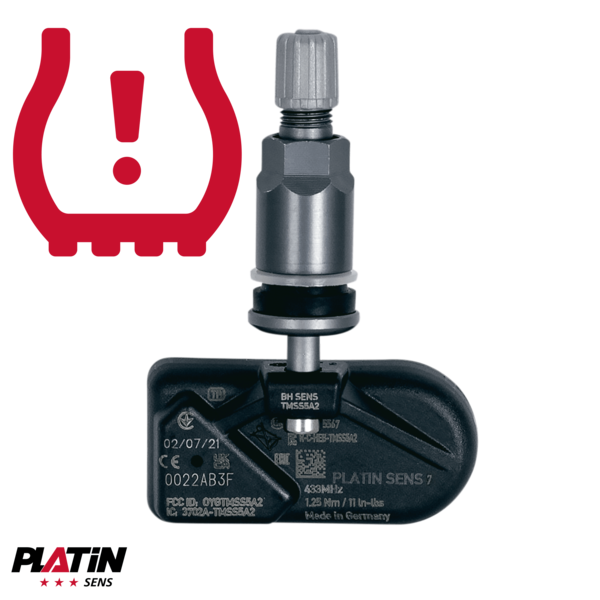

PLATIN Sens with a metal valve have a fixed valve angle (10°) and are lightweight.

The sensors are available in silver, grey and black – to match the colour of your wheels. There is also a version with a rubber valve.

TPMS sensor with silver metal valve.

TPMS sensor with grey metal valve.

TPMS sensor with black metal valve.

TPMS sensor with black rubber valve.

PLATIN Sens are hybrid sensors that already incorporate many OE protocols. They can be used like an OE sensor.

PLATIN Sens 1-6 incorporate a total of approx. 155 OE protocols (approx. 90% market coverage).

PLATIN Sens 7 can be programmed universally.

All PLATIN Sens sensors can be reprogrammed at any time with standard diagnostic devices of the manufacturers Ateq and Bartec (separate menu item available).

The EU tyre label helps consumers to decide in favour of a higher fuel efficiency class for their tyres. This can contribute to large reductions in running costs and emissions. Enhanced wet grip means greater road safety, and details of external rolling noise contributes to a reduction in traffic noise levels.

The actual fuel savings and road safety depend heavily on the behaviour of drivers, and in particular on the following:

Less rolling noise saves fuel and cuts CO2. This property is assigned to classes A to E.

Wet grip is assigned to classes A to E. Wet grip is crucial to safe driving. For instance, the difference between class A and class E braking distances is 18 m.

The label presents the volume in dB and the class A (quieter), B, or C (louder). The noise emitted by tyres affects the total noise levels emitted by the vehicle.

The snowflake symbol confirms that the snow tested tyre keeps within the 3PMSF limits (type approval).